3D printing technology has come a long way since first hitting the market, from rapid prototyping to full production processes – 3D printing continues to disrupt industries worldwide.

For instance, Camper Shoes relies on 3D printers to quickly iterate designs. Their 3D printers’ fast iteration process, combined with printing parts from a variety of materials, allow Camper to create more innovative products quickly. You can always go for quality options, like resin 3D printer models from Elegoo.

Origins

3D printing’s roots go back to the 1980s, when inventors attempted to develop systems for manufacturing. At that time, Hideo Kodama, an innovator, developed an additive manufacturing technique using photosensitive resin solidified with UV light that created three-dimensional shapes.

Hull created the STL file format to facilitate creation of three-dimensional models on computers before sending it directly to printers for production in physical form.

3D printing has quickly become an indispensable asset across various industries. It enables companies to quickly test new products at lower costs than using traditional techniques, and create complex geometries which would otherwise be hard to produce. Furthermore, 3D printing has even been explored as a potential means for creating homes and cities as it allows the printing of entire buildings in just one run while using different materials simultaneously.

Before an object can be 3D printed, it must first be designed in virtual environment using various programs – including computer-aided design (CAD) software – before being prepared for printing by slicing it into layers for laser or nozzle printing. Once complete, an assembled object should appear almost identical to its original. A successful print should look and feel exactly like its source object.

Applications

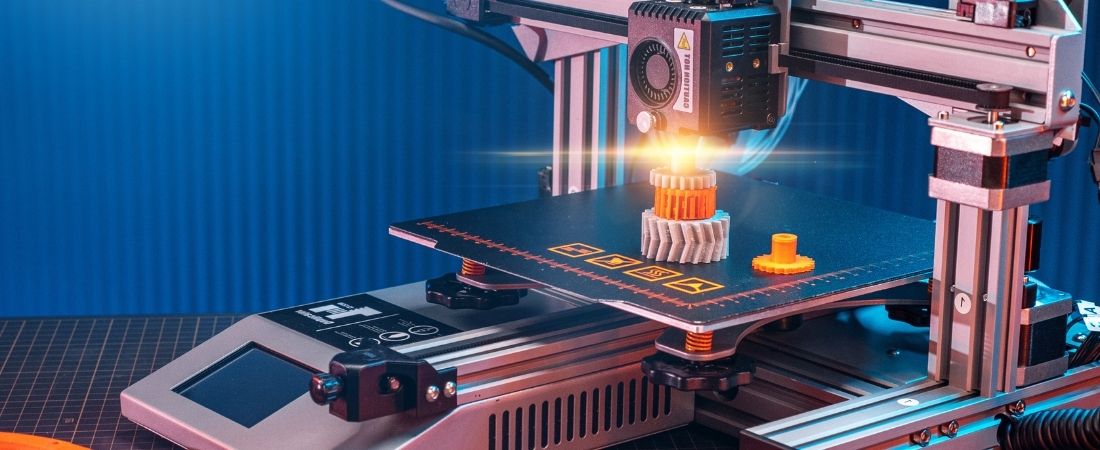

3D printing works by creating three-dimensional objects from digital models. This can be accomplished via various processes, such as fused deposition modeling (FDM), stereolithography (SLA), selective laser sintering (SLS) and polyjet printing; FDM is the most popular approach, using material extrusion to layer upon layer of material until we reach our final product.

Tech experts anticipate that 3D printing will revolutionize how we produce products, from advanced aerospace components to medical implants and jewelry. Customization through 3D printing could increase ergonomics and comfort, with inventory costs anticipated being decreased through this technology.

3D printing offers companies an efficient alternative to traditional manufacturing techniques, which are usually slower and time-consuming. 3D printing enables companies to produce prototypes quickly – cutting down review time for designs before approval for production as well as eliminating shipping requirements for inspection or review in multiple locations.

3D printing now has many uses, from designing prototypes and building buildings to even living communities. Many of these new applications stem from recent advances in 3D technology that enable more materials and faster processes to be utilized in printing processes.

3D printers can be used to produce architectural models and prototypes, jewelry and toys; as well as materials not compatible with conventional fabrication techniques like metals and ceramics. Furthermore, this technology is being utilized as an alternative manufacturing process in some instances such as making dental aligners or repairing broken parts.

Materials

Plastic, resin and ceramic materials can all be used in 3D printing; plastics and resin are particularly common materials, while metal and ceramic ones have their own distinct benefits as well. When choosing materials for 3D printing projects it is essential that the right one be chosen; some materials can reduce waste through recycling while others offer increased strength or durability or better surface finish; still others make printing simpler, producing more detailed prints than ever.

3D printing allows companies to accelerate product development by speeding up the design and testing processes more quickly, with rapid iteration and prototyping capabilities that enable more innovative products. Furthermore, using this manufacturing technology reduces carbon footprint by cutting material waste and shipping requirements, as well as helping manufacturers lower carbon emissions through waste minimization efforts.

3D printers enable designers to produce intricate, customized designs that would otherwise be impossible with traditional manufacturing processes. 3D printing technology has proven useful for creating prototypes and functional parts for applications ranging from medical devices to consumer goods; such as prosthetics where e-NABLE, an online community of volunteers using 3D technology has improved how prosthetic hands and arms fit and function.

Other applications of 3D printing include creating educational models to enable students to see how their designs will appear in reality, medical models that allow doctors to practice procedures before surgery and providing comfortable dwellings for families displaced by natural disasters. Furthermore, in-house production allows businesses to protect intellectual property and maintain confidentiality – two essential considerations when producing sensitive designs.

Costs

Many factors affect expenses, including type and size of filament used and print size. Standard PLA filaments usually cost $20 per kilogram while more specialized engineering filaments could run into triple figures per kg; additionally, specialty composite resins could range between $50-200 per kilogram.

Energy costs can also be an important consideration, with business owners seeking to optimize the return on their investments or hobbyists wanting to reduce energy consumption being especially concerned about this aspect of 3D printing. However, optimizing print settings can help lower this expense significantly.

Post-processing costs can also have an effect on overall printing expenses. Your choice to DIY post-process or hire professional will have an effect on what your prints will cost; while DIY may be more affordable and require specific skillset.

Costs associated with 3D printing depend heavily on the complexity of a design. Larger and more intricate structures may require more materials and take longer to print, while simpler, smaller designs tend to be less costly. Wall thickness and layer height selection can have an impactful effect as thicker walls may help decrease print time while thinner layers add greater detail.

Technology

3D printing is a manufacturing process that utilizes layers of material to produce objects using Fused Deposition Modelling or FDM, using thermoplastic materials such as ABS or PLA that are recyclable and reusuable, providing extreme flexibility when it comes to design and construction of printed items. The most popular method is known as Fused Deposition Modelling or FDM and uses this approach. It is the preferred technique due to its layering technique which enables greater design freedom as well as recycling opportunities for printed items.

To prepare a model for printing, CAD software (a type of computer program that creates precise drawings and technical illustrations) must first create its virtual design. After breaking it down into hundreds or even thousands of thin, horizontal layers that will later be printed separately before being assembled together into the final object. While this technology offers high levels of accuracy when producing parts individually, traditional molding and machining technologies provide greater volume production opportunities while printed items’ surface finish often leaves visible layer lines, necessitating additional finishing processes.

Furthermore, this form of production reduces inventory costs as companies can manufacture parts only when needed – providing companies with cost savings by manufacturing parts on demand.

3D printing offers an eco-friendly alternative to traditional manufacturing techniques. It produces less waste, requires only what materials are necessary, uses fewer resources and reduces energy usage, plus production can occur on-site reducing intellectual property rights violations and maintaining confidentiality; and reduce carbon emissions associated with shipping products overseas.