Packing heavy machinery is a complex task that requires precision, planning, and attention to detail. The risks associated with transporting heavy equipment are significant, and improper packing can lead to damage that is costly to repair and potentially dangerous. Whether you’re moving machinery across town or shipping it internationally, the way you pack it will determine its safety during transit. This step-by-step guide will provide you with the essential practices to achieve safe machinery packing, ensuring your heavy equipment arrives in pristine condition.

Step 1: Assess the Machinery’s Specifications

The foundation of successful machinery packing lies in understanding the specific requirements of the machinery. Begin by assessing the equipment’s weight, dimensions, and delicate components susceptible to damage. This step is crucial because it dictates the type of packaging materials and methods you’ll use. For example, heavier machinery might require reinforced wooden crates or pallets to support its weight, while sensitive parts may need additional protective measures such as foam padding or cushioning to avoid damage. The more thorough your assessment, the better equipped you will be to pack the machinery effectively.

Step 2: Select the Right Packaging Materials

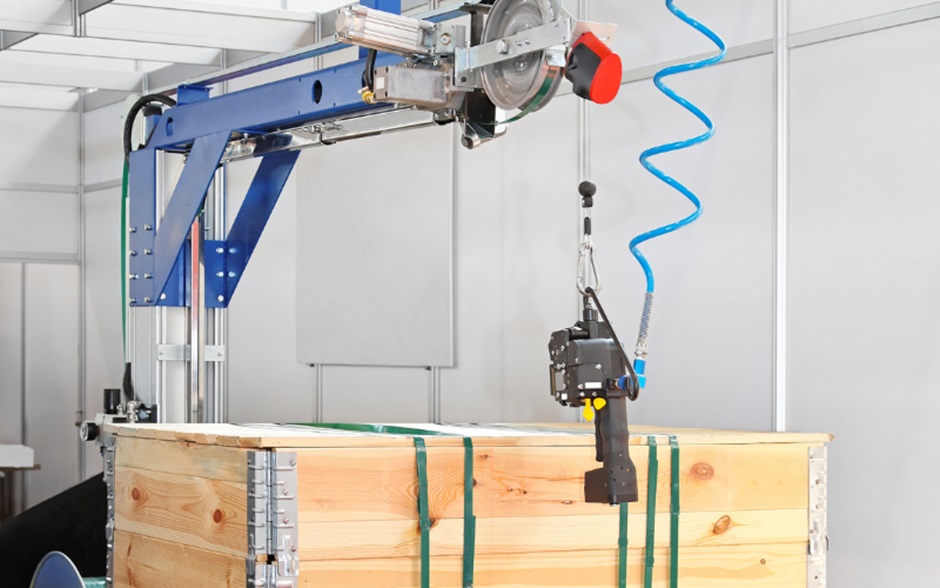

After assessing the machinery, the next critical step is to choose the appropriate packaging materials. The materials must be robust enough to handle the machinery’s weight and protect it from external factors during transport. Wooden crates are commonly used for heavy machinery packaging due to their strength and durability. They can withstand the pressure of stacking and the wear and tear of transit. In some cases, it may be necessary to use moisture-resistant materials, especially if the machinery contains components vulnerable to rust or corrosion. Investing in high-quality packaging materials is essential, as they provide the first defence against potential damage during transportation.

Step 3: Secure the Machinery Properly

Securing the machinery within the packaging is perhaps the most crucial step in the packing process. Once the machinery is placed inside the crate or on a pallet, it must be immobilised to prevent movement during transit. Movement can lead to shifting, which increases the risk of damage. Use formidable, industrial-grade straps or tie-downs to secure the machinery. Additionally, consider using bracing or blocking to hold the machinery in place. It’s also critical to ensure that all delicate components are cushioned appropriately to absorb shocks or vibrations.

Step 4: Label and Document the Package

Once the machinery is packed and secured, the next step is to label and document the package. Proper labelling is essential to communicate handling instructions to those involved in the transportation process. Labels such as “Fragile,” “Heavy Load,” or “This Side Up” guide handlers on how to move and position the package. Moreover, comprehensive documentation should accompany the package, detailing the contents, specifications, and special handling requirements. This documentation is crucial for tracking and verifying the shipment, especially if the machinery is transported over long distances or internationally.

Step 5: Conduct a Final Inspection

Before the machinery is dispatched, it is imperative to conduct a final inspection. This step involves a thorough check to ensure that all aspects of the packing process have been correctly implemented. Inspect the integrity of the packaging materials, verify that the machinery is securely fastened, and ensure that all labels and documentation are in place and visible. The final inspection acts as a safeguard, catching any potential issues before they become problems during transit. If any deficiencies are found, address them immediately.

Conclusion

Safe and secure machinery packing is not just about placing equipment in a box; it’s about ensuring that every step of the process is executed with precision and care. By following these steps—assessing the machinery’s specifications, selecting the right packaging materials, securing the machinery properly, labelling the package, and conducting a final inspection—you can ensure your heavy machinery is well-protected during transit. Proper machinery packing is an investment in the safety and longevity of your equipment, ensuring that it reaches its destination ready to perform as expected.

For more information about machinery packing solutions, contact Sin Chew Woodpaq today.