In the dynamic world of electrical engineering, accuracy is not just a virtue; it’s a necessity. From intricate circuitry to sophisticated power systems, the reliability of electrical measurements can make or break a project. This is where electrical calibration steps in, serving as the bedrock of precision in electrical testing and instrumentation.

Defining Electrical Calibration

Electrical calibration is the systematic process of adjusting and verifying the accuracy of electrical test equipment to ensure consistent and reliable measurements. It involves comparing the instrument’s readings to known reference standards and making adjustments as needed to minimize deviations. Through meticulous calibration, engineers can trust the integrity of their data and make informed decisions with confidence.

The Significance of Electrical Calibration

The importance of electrical test equipment calibration extends far beyond mere technicality. Here’s why it’s indispensable:

- Reliability: Calibrated equipment ensures reliable measurements, fostering trust in the data collected and the decisions based on it.

- Accuracy: By fine-tuning instruments to recognized standards, calibration guarantees precise readings, even in the most demanding applications.

- Compliance: Many industries have stringent regulations mandating the use of calibrated equipment for quality control and regulatory compliance. Calibration ensures adherence to these standards.

- Risk Mitigation: Regular calibration helps identify and rectify deviations early, reducing the risk of inaccuracies, product failures, and safety hazards.

- Efficiency: Calibrated instruments minimize the need for rework and troubleshooting, streamlining processes and optimizing productivity.

Types of Electrical Calibration

Electrical calibration encompasses a diverse array of instruments and devices, each requiring specialized calibration procedures. Some common types include:

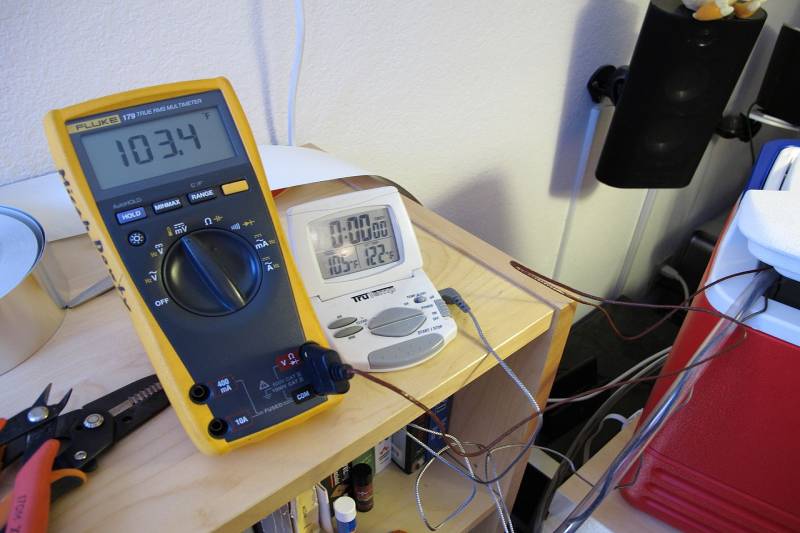

- Multimeter Calibration: Multimeters are versatile tools used for measuring voltage, current, and resistance. Calibration ensures their accuracy across various ranges and functions.

- Oscilloscope Calibration: Oscilloscopes are indispensable for analyzing electrical waveforms. Calibration ensures precise waveform representation and timing accuracy.

- Power Analyzer Calibration: Power analyzers are essential for assessing the quality of electrical power. Calibration guarantees accurate measurement of parameters such as voltage, current, power factor, and harmonics.

- Insulation Tester Calibration: Insulation testers assess the integrity of electrical insulation in systems. Calibration ensures reliable detection of insulation faults and breakdown voltages.

The Calibration Process

While the specifics may vary depending on the instrument, the calibration process typically follows a structured approach:

- Preparation: Inspect the equipment for damage and cleanliness, ensuring optimal conditions for calibration.

- Verification: Compare the instrument’s readings to traceable reference standards to assess its accuracy.

- Adjustment: Make necessary adjustments to align the instrument’s readings with the reference standards, minimizing errors.

- Validation: Validate the instrument’s performance post-adjustment to confirm compliance with specifications.

- Documentation: Document the calibration results, including adjustments made and calibration dates, to maintain a comprehensive calibration history.

Choosing a Calibration Partner

Selecting the right calibration partner is pivotal in ensuring the effectiveness of the calibration process. Consider the following factors:

– Accreditation: Opt for a calibration provider accredited by relevant authorities, ensuring adherence to industry standards and best practices.

– Expertise: Look for a provider with extensive experience and expertise in calibrating a diverse range of electrical instruments.

– Facilities: Assess the provider’s calibration facilities, ensuring they possess state-of-the-art equipment and adhere to rigorous calibration protocols.

– Turnaround Time: Consider the provider’s turnaround time for calibration services, ensuring minimal disruption to operations.

– Customer Support: Choose a provider known for excellent customer support and responsiveness to inquiries and service requests.

Electrical calibration serves as the cornerstone of precision in electrical measurements, ensuring accuracy, reliability, and compliance in diverse applications. By embracing rigorous calibration practices and partnering with trusted calibration providers, engineers can navigate the complexities of electrical testing with confidence, propelling innovation and excellence in the field of electrical engineering.